Tier-02

Tier 2: Cold-Formed Steel (CFS) Framing

“Digitally enabled manufacturing with global reach.”

Material Access: Produced via FrameCAD-like machines located globally or mobilized onsite.

Infrastructure: Requires compact digital fabrication tools; faster than timber but less infrastructure-heavy than extrusions.

Logistics: Homes can be delivered as:

Kits of parts

Pre-assembled modular elements

Turnkey mobile units

Best for: Large-scale affordable housing, urban infill projects, mid-rise development.

Advantages

This construction tier is centered around advanced cold-formed steel (CFS) framing, utilizing automated manufacturing technologies integrated with design software—most notably systems like FrameCAD. These solutions combine precision engineering with scalable, on-demand production capabilities, making this hybrid of traditional and automated construction both highly efficient and increasingly accessible worldwide.

Lightweight steel stud framing is commonly employed in commercial construction and multi-story residential projects. With the emergence of companies offering portable, software-integrated roll-forming equipment, this method now enables a decentralized approach to manufacturing, allowing for consistent quality across multiple regions operating within the same system.

Key Benefits

Regulatory Acceptance: This tier supports code-compliant, permanent structures, and is broadly accepted by local building departments, including permitting across all 50 U.S. states.

Speed of Assembly: Steel framing accelerates the pace of construction significantly, often allowing the structural form of the building to be realized within days.

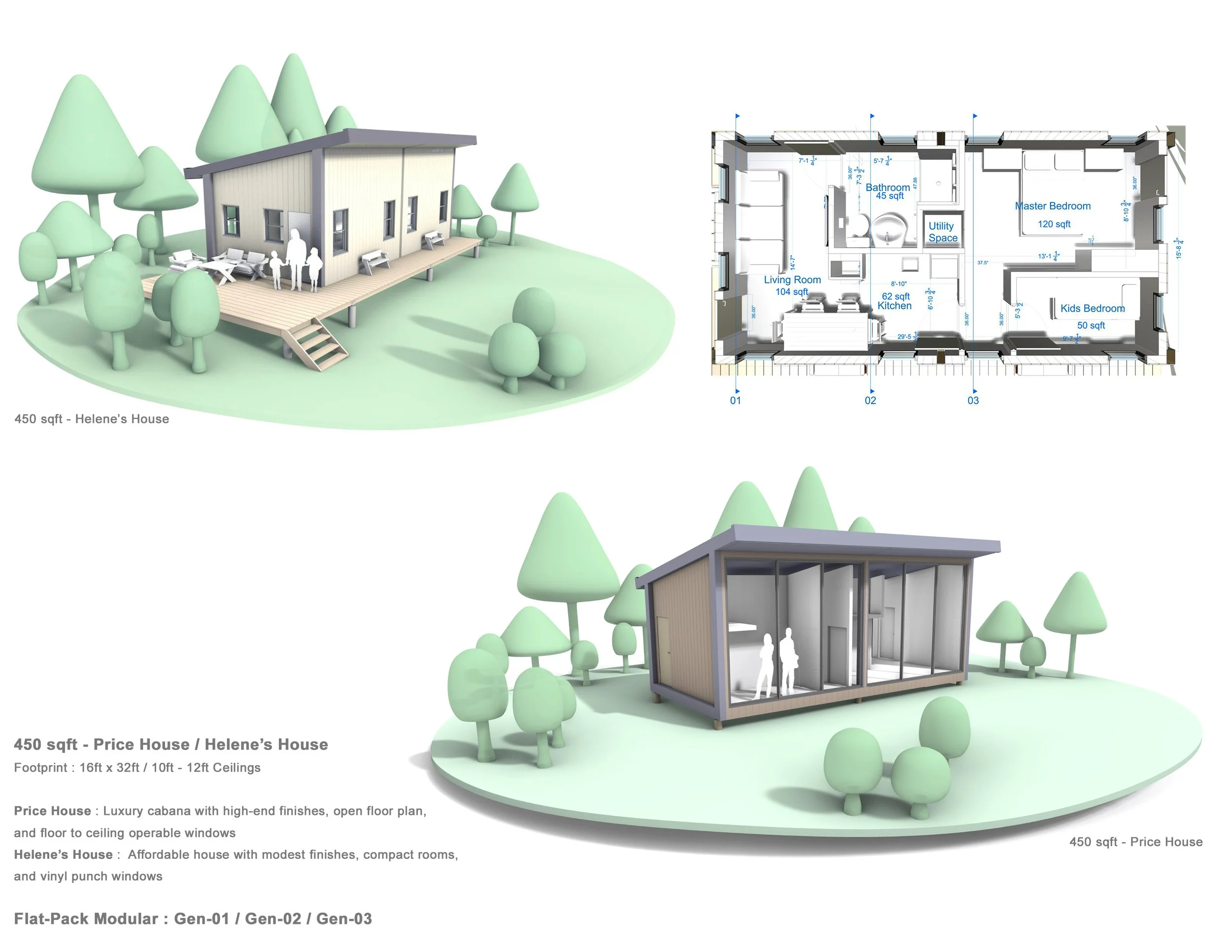

Versatile Delivery Formats:

Flat-packed kits for on-site assembly, similar to furniture

Pre-fabricated elements that connect modularly like building blocks

Fully assembled modules that require only utility hookups

Material Accessibility

Material availability is closely linked to factory proximity. One of the core advantages of this system is its mobility—lightweight, compact manufacturing units can be deployed directly to, or near, the job site, minimizing supply chain complexities.

Infrastructure Requirements

The infrastructure needed to support Tier 2 construction is minimal compared to traditional manufacturing facilities. The mobile nature of the equipment enables flexible deployment without significant capital investment in permanent infrastructure.

Logistics

Logistical considerations for this construction tier are highly adaptable. By enabling local or on-site manufacturing, transportation costs and lead times are drastically reduced, making this an ideal solution for both urban infill and remote development projects.